The Truth About Auto Repair: What 15 Years Under the Hood Taught Me

The Truth About Auto Repair: What 15 Years Under the Hood Taught Me

I quit the auto repair business in 1998. After fifteen years of watching good mechanics get corrupted and customers get ripped off daily, I couldn't take it anymore. The industry I entered in 1982 wanting to help people keep their cars running had turned into something ugly. Honest mechanics struggled to pay rent while crooks bought new trucks every year.

When I first wrote about this in 2000, other mechanics started reaching out. They shared their own stories. Turns out what I saw wasn't just a few bad shops. This stuff happens everywhere.

Cars today are computers on wheels. They're more complex than ever. But the same rotten system that corrupted the industry twenty years ago is still there. It's actually gotten worse.

How Mechanics Really Get Paid

Most people don't know how auto repair actually works. They think mechanics get hourly wages like other jobs. That's not true. Almost every mechanic in America gets paid through something called "flat rate."

Here's how it works. Car companies publish books that say how long each job should take. Replace a water pump? That's 3.2 hours. Change brake pads? Maybe 1.5 hours. These times are set in stone.

The mechanic gets paid those book hours no matter what. Finish the water pump in two hours? Still get paid 3.2. Take all day because you hit problems? Still 3.2 hours.

Most mechanics work straight commission. No "flagged" hours means no paycheck. I've seen good mechanics flag 16 hours in an 8-hour day when they're fast. I've also seen mechanics work a full week and barely flag 20 hours because work was slow.

The shop takes about half of what you pay. So they want mechanics flagging as many hours as possible too. More flags means more money for everyone. Except you.

This system is toxic. It rewards speed over accuracy. Volume over honesty. The fastest parts-swapper makes more money than the best diagnostic expert. That's backwards.

Why Good Mechanics Turn Bad

I watched this happen over and over. A guy starts out wanting to fix cars properly. He's careful. Takes time to diagnose things right. Explains problems to customers honestly.

Then reality hits. His paychecks suck. Meanwhile the guy next to him is making twice as much by selling parts people don't need. Management praises the high producer. Gives him bonuses. "Mechanic of the month" awards.

The honest guy can't pay his bills. His family suffers. The pressure builds.

Most crack eventually. They start recommending "preventive" replacements. Selling multiple parts for single problems. Before long, they're full-blown con artists who sleep fine at night.

I saw mechanics go from wanting to help people to viewing customers as marks to be fleeced. The flat rate system breaks good people. It has to. Honesty is a luxury most mechanics can't afford.

The transformation doesn't happen overnight. It's a gradual slide. First, maybe they start recommending air filter changes a little early. "Better safe than sorry," they tell themselves. Then they suggest replacing parts that are "getting close" to failure. Before they know it, they're selling complete brake jobs to cars that only need pads.

The really tragic cases are the guys who fought it longest. I knew one mechanic who lasted eight years trying to stay honest. He had real diagnostic skills. Could trace electrical problems that stumped everyone else. But he made half what the parts-swappers earned. His wife left him because he couldn't provide for their kids. That's when he snapped.

Within six months, he went from being the most trustworthy guy in the shop to one of the biggest crooks. Started claiming every car needed extensive electrical work. Would replace entire wiring harnesses when the problem was a loose connection. Made more money in those six months than he had in the previous two years combined.

The worst part? Management loved his "turnaround." Suddenly he was their star performer. Got praised at company meetings. Received bonuses and incentives. The system was rewarding him for becoming everything he'd originally stood against.

The Parts Swapping Epidemic

Here's something most car owners don't know. About 75% of mechanics can't actually diagnose problems. They're parts swappers. They throw components at symptoms until something works or you run out of money.

This is incredibly profitable. Each part generates billable hours. And there's always a logical-sounding reason why "this sensor could be causing your problem."

Electronic parts make this scam easy. About half get returned to manufacturers as "no fault found." That means they worked fine when removed. They were misdiagnosed. But the customer already paid for replacement and labor.

I've seen mechanics replace $500 worth of sensors to fix a problem caused by a $5 vacuum hose. Customer pays everything. Mechanic flags hours for each part. Shop gets their cut. Everyone wins except the person writing the check.

Sometimes parts swapping accidentally works. A bad vacuum hose causes weird symptoms. The mechanic replaces a nearby sensor. The symptoms seem to go away temporarily. Customer drives off thinking they're fixed. Three weeks later, the real problem shows up again.

The vacuum hose example isn't theoretical. I watched it happen dozens of times. Cars would come in with rough idle or hesitation problems. The real cause was usually a cracked vacuum line that cost pennies to fix. But these lines are hard to see and take time to inspect properly.

Instead of spending twenty minutes tracing vacuum lines, parts-swappers would start replacing expensive sensors. Mass airflow sensors, throttle position sensors, idle air control valves. Each replacement generated an hour or two of labor charges plus markup on the parts.

The customer would spend $400-500 getting multiple sensors replaced. The car might run slightly better because one of the new sensors was marginally better than the old one, even though the old one was fine. But the underlying vacuum leak remained. A month later, the same symptoms would return, often worse than before.

Then the customer would come back, frustrated that their "expensive repairs" didn't last. The same mechanic would claim the problem had "spread to other systems" and recommend even more parts. I've seen customers spend over $2000 chasing problems that could have been fixed for under $10 with proper diagnosis.

The really sophisticated parts-swappers develop a methodology. They learn which combinations of sensors and modules commonly fail together on specific vehicle models. When a customer comes in with symptoms that could indicate any of several problems, they recommend replacing the entire group of "related" components.

This approach sounds professional to customers. The mechanic explains how "these systems work together" and how "one failure often causes others." It's all technically true, but it ignores the fact that most problems have single root causes that don't require multiple part replacements.

When Your Check Engine Light Comes On

Modern cars are smart. When something goes wrong, the computer stores a fault code. This code points to the problem area. It's valuable information. If you know how to use it.

Most shops treat codes like shopping lists. Code says "oxygen sensor"? Replace oxygen sensor. Code says "transmission problem"? Time for a rebuild.

But codes don't tell you what to replace. They tell you where to start looking. An oxygen sensor code could mean the sensor is bad. Or the wiring is damaged. Or there's an exhaust leak. Or the fuel is contaminated. Or a dozen other things.

A real diagnostic expert tests the sensor. Checks the wiring. Verifies the system is working right. Only then do they recommend parts.

A parts swapper just starts changing things and hopes something works.

The flat rate system makes this worse. Proper diagnosis takes time but doesn't pay much. Parts replacement pays well and goes fast. Guess which approach gets rewarded?

I spent years trying to explain this to customers, but most didn't want to hear it. They'd bring their car in with a check engine light and expect a quick answer. When I said I needed time to diagnose the problem properly, they'd get impatient. "Can't you just plug in your computer and see what's wrong?"

The irony is that customers often complained about being overcharged, but they created demand for the very practices that inflated their bills. Quick fixes and educated guesses are cheaper upfront but usually cost more in the long run when the real problems remain unfixed.

I remember one customer who came in with a check engine light and rough idle. The code indicated a problem with the exhaust gas recirculation system. A proper diagnosis would have taken about an hour and revealed a stuck EGR valve that needed cleaning - maybe $50 total.

But the customer was in a hurry and didn't want to pay diagnostic time. He authorized replacement of the EGR valve without testing. The part cost $180 plus an hour of labor. The car ran fine when he picked it up.

Two months later, he was back with the same symptoms. This time, a different mechanic actually diagnosed the problem. The EGR valve was fine - it was the new one we'd installed. But the vacuum line that controlled it was cracked, causing the exact same symptoms as a bad valve. Five dollars for a new vacuum line fixed the car permanently.

The customer paid twice as much as necessary and went two months with an unfixed problem, all because he didn't want to "waste money" on proper diagnosis the first time.

Stories from the Trenches

Let me tell you about some things I actually saw happen.

The New Car Scam: One dealer I worked at had a system. New cars came off the truck and immediately got written up for problems. Alignment issues. Transmission trouble. Engine performance. Three different mechanics would flag maximum time for "fixing" these problems. Except they did zero work to most cars.

This went on for over a year. Some mechanics made six figures from fake warranty claims. When the manufacturer finally caught on, the dealership got shut down. Those same mechanics just moved to other dealers.

The Old Lady: I watched a mechanic sell an elderly woman $2,000 worth of parts over three visits for a car that had a rough idle. He replaced sensors, modules, computer parts. The car still ran rough every time she picked it up.

Finally another mechanic checked it properly. Bad spark plug wire. Fifteen bucks. The woman never got her money back. None of those unnecessary parts got removed either.

The Engine Faker: One guy I knew specialized in fake engine rebuilds. He'd tell customers they needed new pistons and rings. Flag massive hours for tearing down engines and rebuilding them. Then do absolutely nothing to the actual engine.

His technique was smooth. He'd replace a few visible gaskets so things looked different. But the internal parts stayed untouched. Customers paid thousands for work that never happened.

The new car scam was particularly elaborate. This dealership had convinced the manufacturer they were exceptionally thorough with pre-delivery inspections. They claimed to be catching problems that other dealers missed, which explained their unusually high warranty claim rates.

In reality, they had a rotating system where three mechanics would take turns "working on" each new vehicle. The first would claim alignment problems and flag two hours for adjustments that never happened. The second would diagnose transmission issues requiring fluid changes and calibrations that were never performed. The third would find engine performance problems requiring computer reprogramming that consisted of plugging in a scan tool for five minutes.

Each mechanic flagged maximum allowable time for their fake repairs. The shop collected from the manufacturer for all the labor and parts that were supposedly used. The vehicles went to customers as "thoroughly inspected and corrected" when they'd never been touched.

This particular operation was generating over $200,000 per month in fraudulent warranty claims. Some individual mechanics were making $150,000 per year just from this scam, not counting their regular customer-paid work.

When manufacturer auditors finally showed up for a surprise inspection, they found dozens of "repaired" vehicles that had never been worked on. The paper trail showed extensive repairs, but the actual vehicles showed no evidence of any work being performed.

The dealership's warranty claim rate was running about ten times higher than similar stores in the region. Every single new vehicle was supposedly requiring major corrections before delivery. The mathematical impossibility of this should have triggered investigation much sooner.

Maintenance Scams That Never Die

Shops make huge profits from unnecessary maintenance. These scams work because they sound reasonable to people who don't understand cars.

Fuel System Cleaning: Back in the 1980s, fuel injectors got clogged regularly. They needed professional cleaning. The service took about an hour but only needed 15 minutes of actual work.

Then fuel companies added detergents. Car makers made better injectors. The clogging problem disappeared in the late '80s.

But shops still push fuel cleaning today. They charge an hour of labor for something modern cars don't need. When you ask why, they say "preventive maintenance" or "fuel quality varies." Both are lies.

Throttle Body Cleaning: Same story here. Old throttle bodies needed cleaning. Modern ones don't. Some actually come with special coatings that cleaning removes. This can cause idle problems that didn't exist before.

Shops still sell this service. Takes five minutes, charges an hour. Often makes cars run worse.

The Fake Tune-Up: This might be the biggest scam of all. Modern cars don't need tune-ups. Everything is computer controlled. Timing adjusts automatically. Idle speed regulates itself. Fuel mixture optimizes constantly.

Today's cars need spark plugs at maybe 100,000 miles. That's it. No adjustments exist to make.

But shops still sell "tune-up packages" that include services your car doesn't need and adjustments that don't exist.

The fuel system cleaning scam has evolved into multiple variations. Basic fuel injection cleaning has been joined by "upper engine cleaning," "intake valve cleaning," and "direct injection service." Each claims to address specific problems with modern engines, but most are unnecessary on properly maintained vehicles.

I've seen shops sell $300 fuel system services to cars with less than 30,000 miles. The sales pitch focuses on "carbon buildup" and "deposit formation" that supposedly occurs even with good gasoline and proper maintenance. They show customers impressive-looking equipment and before-and-after photos that may not even be from their vehicle.

The throttle body cleaning scam is particularly insidious because it can actually create problems. Many modern throttle bodies are calibrated at the factory with specific coatings or surface treatments. When shops clean these surfaces with harsh chemicals, they remove calibrated materials that affect airflow characteristics.

The result can be irregular idle speed, poor throttle response, or even check engine lights that weren't present before the "cleaning." The customer then needs additional repairs to fix problems caused by the unnecessary service they were sold.

I watched one customer bring his nearly new car in for an oil change and get talked into throttle body cleaning. The car had been running perfectly. After the service, it developed an erratic idle and poor acceleration. The shop claimed this proved the service was needed because "all that crud was affecting performance."

In reality, the cleaning had damaged the throttle body's calibrated bore coating, creating the exact problems it was supposed to prevent. The customer ended up needing a new throttle body assembly under warranty, but the connection to the unnecessary cleaning service was never acknowledged.

Red Flags That Should Scare You

After seeing thousands of scams, I learned to spot the warning signs.

Multiple Parts for One Problem: If your mechanic wants to replace several parts to fix one issue, be very suspicious. While it's possible for multiple things to fail at once, usually one root cause creates multiple symptoms.

Ask for detailed explanations. How does each part relate to your problem? Good mechanics can explain this clearly. Parts swappers give vague answers about "systems working together."

Non-Factory Maintenance: If it's not in your owner's manual, question it hard. Modern cars need very little maintenance. Oil changes, filters, brakes when worn, spark plugs at long intervals. That's about it.

Transmission flushes, cooling system cleanings, and other services usually aren't needed unless something is actually wrong.

Early Brake Replacement: Brake pads can run down to about 15% before replacement. Many shops try to sell brakes at 50% or higher. Ask to see your actual brake pads. Good shops will show you what they're talking about.

Too Much Diagnostic Time: Any problem that happens consistently should get diagnosed in a few hours max. Intermittent problems are harder and might take longer. But be wary of shops that want to spend days throwing parts at problems without a clear plan.

The multiple parts red flag is probably the most important warning sign customers can learn to recognize. Legitimate multiple failures do occur, but they're much less common than shops would have you believe.

When multiple parts genuinely need replacement, there's usually a clear mechanical relationship. A failed water pump might damage the thermostat due to overheating. A broken timing belt could bend valves and damage pistons. These cause-and-effect relationships are easy to explain and verify.

But many shops recommend multiple parts when they can't identify the actual problem. Instead of admitting they don't know what's wrong, they hedge their bets by recommending everything that might possibly be related to the symptoms.

I've seen customers get presented with repair estimates listing six or eight different components that "all need replacement" to fix a single symptom. When pressed for explanations, the mechanic gives vague answers about how "these systems work together" without being able to explain the specific failure modes.

One customer brought me an estimate from another shop that included: mass airflow sensor, throttle position sensor, idle air control valve, oxygen sensors, vacuum lines, PCV valve, air filter, and fuel filter. Total cost was over $800 to fix a rough idle condition.

I spent thirty minutes with a vacuum gauge and found a cracked intake manifold gasket - a $15 part that took forty-five minutes to replace. The customer's car ran perfectly after the repair, proving that all those other components were unnecessary.

The shop that wrote the original estimate was essentially admitting they couldn't diagnose the problem. Instead of saying "we don't know," they recommended replacing everything that could possibly cause the symptoms. This approach guarantees they'll fix the problem eventually, but at enormous cost to the customer.

Finding Honest Mechanics

They still exist. You just have to know where to look.

Find Specialists: Cars are too complex for one person to know everything. Look for shops that specialize. Transmission guys. Electrical experts. Engine performance specialists. Someone who focuses on your type of problem is more likely to fix it right the first time.

Avoid the Stars: Be suspicious of "mechanic of the month" winners. These awards usually go to whoever flags the most hours. That often means the most aggressive salesperson, not the best technician.

Ask Detailed Questions: When you drop off your car, describe symptoms precisely. Don't try to diagnose it yourself. Just explain what happens, when it happens, and how often. Good mechanics ask lots of follow-up questions. They want to understand the problem completely.

Check References Carefully: Personal recommendations help, but verify them. Some people don't realize they've been ripped off, especially if their car seemed better afterward. Ask specific questions about any shop someone recommends.

Fight Back: If you get scammed, don't just accept it. Complain to the shop manager. File reports with consumer agencies. Tell everyone you know. The only way to clean up this industry is to make dishonesty unprofitable.

Finding a good specialist requires some research, but it's worth the effort. A transmission expert who works only on transmissions will know more about your specific problem than a general mechanic who does a little bit of everything.

The challenge is identifying genuine specialists versus shops that just claim expertise they don't have. Real specialists usually have specialized equipment, manufacturer training certificates, and can discuss technical details that general mechanics wouldn't know.

I knew one electrical specialist who could diagnose intermittent problems that stumped everyone else in town. His shop looked like a laboratory, with oscilloscopes, signal generators, and other test equipment that most mechanics had never seen. He charged more per hour than general shops, but he fixed problems correctly the first time.

Customers would drive from hundreds of miles away to have him work on electrical problems that other shops couldn't solve. He was booked weeks in advance, which is usually a good sign. Shops that can fix problems correctly develop reputations that create steady demand for their services.

The downside of specialists is that they may not be convenient for routine maintenance. You probably don't want to drive across town to have your oil changed at the transmission specialist. But for complex problems in their area of expertise, specialists are usually worth the extra time and expense.

The Business Side of Dishonesty

From a business perspective, fraud pays well in auto repair. A crooked mechanic flagging 80 hours a week makes way more than an honest one flagging 35. Management loves high producers because they generate more profit per square foot.

Getting caught has few consequences. Fired mechanics usually just move to other shops. There's no industry blacklist. No professional licensing to revoke. Criminal prosecution is rare for what amounts to theft.

Meanwhile, honest mechanics struggle financially while watching crooks prosper. The industry sends a clear message: integrity doesn't pay.

This creates a vicious cycle. Good people leave the business. They get replaced by incompetent or dishonest ones. Service quality drops while prices rise. Customers get the worst possible deal.

The economic incentives in auto repair are completely backwards. The most skilled diagnosticians often make the least money because they solve problems efficiently. The parts-swappers and con artists make the most because they generate more billable hours through unnecessary work.

I knew one diagnostic expert who could trace electrical problems that other mechanics couldn't even understand. He was absolutely brilliant at systematic troubleshooting. But he struggled financially because he'd spend two hours diagnosing a problem and then fix it in thirty minutes with a $10 part.

Meanwhile, the parts-swapper in the next bay would spend two days replacing random components and generate ten times the billing for the same repair. Management praised the parts-swapper for his "productivity" while the diagnostic expert got criticized for "not flagging enough hours."

This backwards system drives competent people out of the industry while attracting incompetent ones. The customers lose twice - they pay more money and get worse service. The only winners are shop owners who prioritize short-term profits over long-term reputation.

Some shop owners recognize this problem and try to create better compensation systems. They might pay diagnosticians hourly rates for troubleshooting time, or offer bonuses based on customer satisfaction rather than pure volume. But these enlightened approaches are rare in an industry dominated by flat rate thinking.

The lack of meaningful consequences for fraud makes the problem worse. In most other industries, professionals who repeatedly rip off customers face license revocation, criminal charges, or civil liability that puts them out of business. In auto repair, the worst consequence is usually getting fired - and the crooked mechanic just moves to another shop and continues the same behavior.

The Training Problem

Shops treat training like an expense to minimize, not an investment in quality. When car companies offer courses on new technology, training time usually pays base wages instead of commission rates. Some shops don't pay for training at all.

Think about this incentive. A mechanic can spend eight hours learning proper diagnostic procedures and earn maybe $120. Or stay in the shop and potentially flag twelve hours worth $300-400.

The company is basically saying parts replacement matters more than knowledge. This creates a cycle where the mechanics who most need training have the strongest reason to avoid it.

The result is sophisticated diagnostic equipment in the hands of people who don't understand the systems. Shops spend $50,000 on factory scan tools, then use them like expensive parts catalogs instead of diagnostic instruments.

The training problem has gotten much worse as vehicles became more complex. In the 1980s, a good general mechanic could work on most systems with basic tools and knowledge. Today's vehicles require specialized training for each major system, and the information changes constantly as manufacturers update software and procedures.

Manufacturers offer training courses, but they're expensive and time-consuming. A week-long course might cost $2,000 in tuition plus travel expenses and lost productivity while the mechanic is away from the shop. Many shop owners see this as a pure cost with no immediate return.

The irony is that proper training would actually improve profitability by enabling faster, more accurate diagnosis. A well-trained mechanic can identify problems quickly and fix them correctly the first time. An untrained mechanic wastes time on trial-and-error approaches that frustrate customers and generate comeback repairs.

But the flat rate system obscures this connection. When mechanics get paid the same amount regardless of how long jobs take, there's no obvious financial benefit to improved efficiency. Shop owners see training costs but don't see the productivity improvements that result from better knowledge.

Some manufacturers have started requiring training for warranty authorization, which creates market pressure for shops to invest in education. But this applies only to warranty work, which represents a small fraction of most shops' business. Customer-paid repairs still rely on whatever knowledge mechanics happened to acquire through experience or voluntary training.

Customer Mistakes That Make Things Worse

While shops and mechanics bear most of the blame, some customer behavior makes the situation worse.

Many people expect instant diagnosis. They think computers can immediately identify any problem, like in the movies. In reality, diagnostic systems provide data that humans must interpret. This takes time and skill.

Customers often won't pay for proper diagnosis but will buy expensive parts on educated guesses. This enables parts swapping instead of real problem-solving.

Price shopping without understanding what you're comparing also causes problems. The lowest quote often means the worst service. One shop might plan complete brake service while another only replaces pads. The cheap guy wins the job despite planning inadequate work.

Customer impatience creates demand for quick fixes that often aren't permanent solutions. I've had countless customers who wanted problems diagnosed and repaired in the same day, regardless of complexity. When I explained that proper diagnosis might take several hours, they'd get frustrated and go elsewhere.

These customers often ended up at shops that specialized in quick turnarounds through educated guessing and parts swapping. They'd get their cars back the same day with expensive repairs, but the underlying problems often remained unfixed. A month later, they'd be back with the same symptoms, usually worse than before.

The "just tell me what's wrong" mentality ignores the reality of how complex systems fail. Modern vehicles have hundreds of sensors and dozens of computer modules that interact in ways that aren't always obvious. Proper diagnosis requires systematic testing that takes time to perform correctly.

I remember one customer who brought his car in with an intermittent stalling problem. The symptoms were inconsistent - sometimes the car would stall at idle, sometimes while driving, sometimes not at all. This type of problem requires methodical testing to identify the root cause.

The customer didn't want to pay for diagnostic time. He wanted me to "just fix it" based on his description of the symptoms. When I explained that intermittent problems require systematic diagnosis, he went to another shop that promised a same-day repair.

Three weeks later, he was back. The other shop had replaced the idle air control valve, throttle position sensor, and mass airflow sensor - over $400 worth of parts and labor. The car ran fine for a few days, then started stalling again, worse than before.

I finally convinced him to authorize proper diagnostic testing. It took me about three hours to identify the real problem: a cracked wire in the engine harness that was making intermittent contact. The wire break was so small it was almost invisible, but it was causing random electrical faults throughout the engine management system.

A $20 wire repair fixed the car permanently. The customer had paid over $400 for unnecessary parts that didn't address the real problem, all because he didn't want to "waste money" on proper diagnosis initially.

Regional Differences

I noticed different patterns depending on location.

Small towns tend to be more honest but less competent. Word travels fast, so mechanics who consistently rip people off lose business quickly. But limited exposure to complex problems means small-town mechanics often lack skills for difficult diagnosis.

Big cities are different. With millions of potential customers, shops can afford to burn through clients. The strategy becomes extracting maximum profit from each visit, assuming most people won't return anyway.

Military base areas are particularly bad. Service members have limited time and local knowledge. Some shops specialize in ripping off people who'll transfer away before discovering the fraud.

Wealthy areas enable premium pricing for identical services. The same repair that costs $300 in a working-class neighborhood might sell for $800 in an affluent area with minimal resistance.

The military base phenomenon was particularly disturbing to witness. These shops developed sophisticated techniques for identifying and targeting service members who were vulnerable to high-pressure sales tactics.

Young enlisted personnel were especially susceptible. They often had limited automotive knowledge, tight schedules, and ready access to credit through military banking systems. Unscrupulous shops would offer financing plans that made expensive repairs seem affordable through low monthly payments.

I watched one shop systematically target military families by offering "military discounts" that were actually higher than their regular prices. They'd claim special expertise with "military-grade vehicles" - which was nonsense, since military members drove the same civilian cars as everyone else.

The financing scams were particularly predatory. Shops would arrange loans through third-party companies at high interest rates, then inflate repair costs to maximize the loan amounts. Service members would end up paying thousands of dollars in interest on repairs that weren't even necessary.

Because military personnel moved frequently, these shops faced minimal consequences for their fraud. By the time customers discovered they'd been ripped off, they were stationed hundreds or thousands of miles away with little recourse for recovering their money.

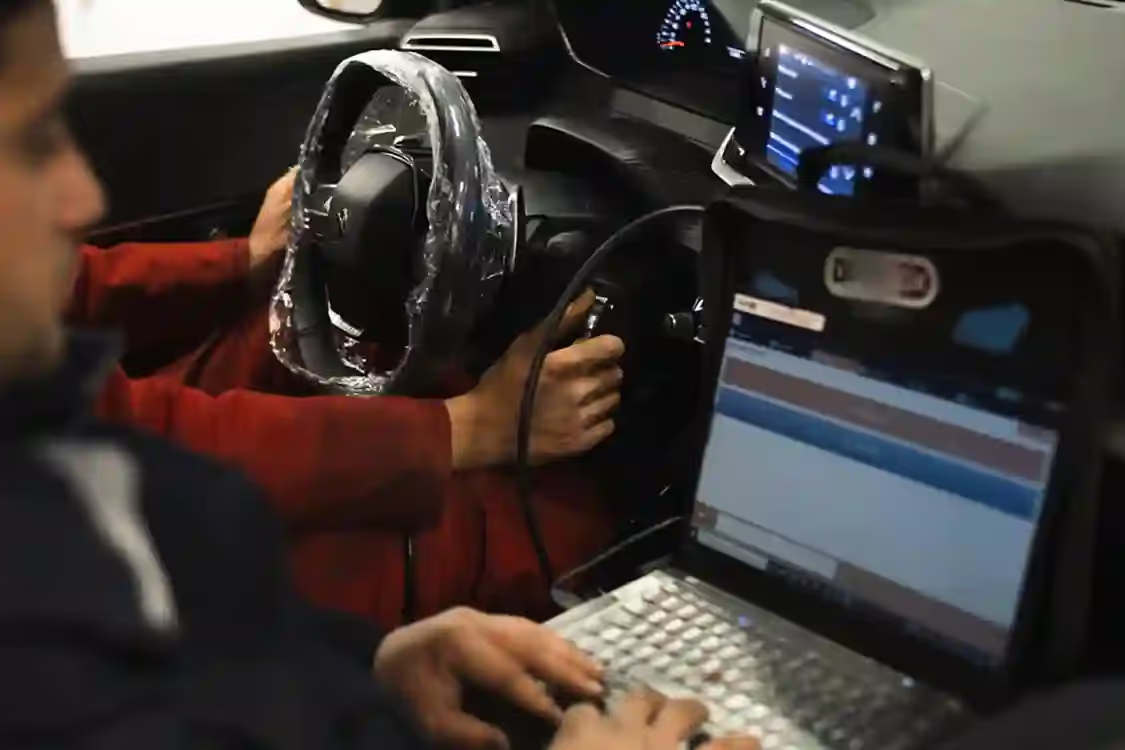

Electronic System Scams

As cars became computerized, new fraud opportunities emerged. Modern vehicles have dozens of computer modules controlling everything from engines to door locks.

Many shops bought expensive diagnostic equipment without training staff properly. The result is sophisticated tools used by people who treat them like parts catalogs instead of diagnostic instruments.

Software problems create symptoms that seem like hardware failures. A corrupted module might cause erratic behavior that appears to implicate sensors or wiring when the real solution is reprogramming.

Dishonest shops exploit customer ignorance by blaming expensive computers for problems with simple causes. A loose connection might make a module malfunction, but replacing the module generates much more profit than cleaning a connector.

System integration enables "cascade billing" - claiming one failure damaged multiple related components. A broken radio becomes a need for new head unit, amplifier, and body control module, all supposedly damaged by the same mysterious problem.

The electronic system scams have become increasingly sophisticated as vehicles incorporate more computer technology. Modern cars have separate modules for engine management, transmission control, anti-lock brakes, airbags, climate control, entertainment systems, and dozens of other functions.

These modules communicate with each other through data networks that most mechanics don't understand. When communication problems occur, symptoms can appear in systems that seem unrelated to the actual fault. This complexity creates opportunities for shops to claim widespread damage from single problems.

I've seen shops recommend replacing five or six different modules to fix problems caused by corroded connections in the main wiring harness. The modules themselves were fine, but communication errors made them appear defective to mechanics who didn't understand network diagnostics.

One particularly common scam involves claiming that software corruption has damaged multiple modules simultaneously. The shop tells customers that a "power surge" or "electrical fault" has affected several computer systems that all need replacement or reprogramming.

In reality, most software problems can be fixed with simple reflashing procedures that take minutes to perform. But customers don't understand the difference between software updates and hardware replacement, so they accept expensive module replacements as necessary repairs.

Insurance Complications

Collision repair has similar issues. Insurance companies negotiate aggressively on rates and procedures, pushing shops to use cheap parts and fast methods.

Some shops respond by inflating damage assessments. Minor fender benders become complex structural repairs. Surface scratches become full panel replacements. This maintains profit margins while costs get passed to all policyholders through higher premiums.

Collision shops often "discover" additional mechanical problems when handling accident damage. While some findings are legitimate, others are just opportunities to generate extra revenue while insurance is paying.

The insurance connection creates opportunities for fraud that don't exist in normal mechanical repairs. When insurance companies are paying bills, customers often don't scrutinize estimates as carefully as they would for out-of-pocket repairs.

I worked briefly at a collision shop where estimators routinely inflated damage assessments by claiming structural damage that didn't exist. A simple bumper replacement would become a complex frame repair requiring specialized equipment and procedures.

The shop had developed relationships with certain insurance adjusters who rarely questioned their estimates. These adjusters were either incompetent or receiving kickbacks for approving inflated claims. Either way, the result was systematic fraud that increased costs for all insurance customers.

Some collision shops also use accidents as opportunities to perform unnecessary mechanical repairs. They'll claim that impact damage affected engine performance, transmission operation, or other systems that weren't actually damaged in the collision.

Customers are vulnerable to these claims because accidents can legitimately cause hidden damage to mechanical systems. A front-end collision might damage cooling system components or affect engine alignment. But many shops exploit this possibility to recommend expensive repairs that aren't actually needed.

The Human Cost

Behind all the economics are real people whose lives get damaged by repair fraud.

I remember a single mother who got talked into $1,500 of unnecessary work with money saved for her daughter's school clothes. When the car still wasn't fixed, she had no money left to get it done right elsewhere.

An elderly man on fixed income got sold a transmission rebuild he didn't need. The work was done poorly with cheap parts. His previously reliable car became a constant problem. He lost independence because he couldn't trust his transportation anymore.

College students were frequent targets. They needed reliable cars for work and school but lacked knowledge to spot scams. I watched young people go into debt for repairs they didn't need, creating financial problems that lasted for years.

The psychological damage goes beyond money. People who discover they've been defrauded become suspicious of all professional services. This makes it harder for honest businesses to build trust and serve their communities.

The stories of individual victims reveal the real human cost of systematic fraud in the auto repair industry. These aren't just financial transactions - they're situations where vulnerable people trusted professionals who betrayed that trust for profit.

The elderly are particularly vulnerable because they often have limited automotive knowledge and fixed incomes that make expensive repairs genuinely painful. I've seen senior citizens choose between necessary medications and unnecessary car repairs because they trusted mechanics who lied to them.

One case that still bothers me involved an 80-year-old woman whose mechanic claimed her car needed a complete engine rebuild. The estimate was over $4,000 - more than her car was worth and most of her savings. She was preparing to authorize the work because she depended on the car for medical appointments.

I happened to overhear the conversation and offered to take a look. The car had a simple vacuum leak that caused rough idle. Fifteen minutes and a $5 part fixed the problem completely. The "engine rebuild" would have bankrupted her for repairs she didn't need.

Young adults face different but equally serious consequences. They often have limited resources and depend on credit to finance repairs. Unnecessary work can create debt problems that follow them for years and affect their ability to buy homes, start families, or pursue education.

I watched college students get talked into expensive repairs they couldn't afford, then struggle to make payments while falling behind in school. Some had to drop out because they couldn't work enough hours to pay for fraudulent repairs and still attend classes.

The ripple effects extend beyond individual victims. Families suffer when breadwinners lose reliable transportation due to botched repairs. Communities lose trust in local businesses when fraud becomes widespread. The entire economy becomes less efficient when resources get diverted from productive uses to unnecessary repairs.

Modern Technology Makes Everything Worse

Today's cars are more complex than the space shuttle that went to the moon. They have hundreds of sensors, dozens of computer modules, and millions of lines of software code. This complexity should make diagnosis more accurate. Instead, it's created new ways to rip people off.

Diagnostic equipment costs have exploded. A factory scan tool can cost $50,000 or more. Software subscriptions run thousands per year. Programming equipment adds another $20,000. Small independent shops can't afford this stuff, so they're forced to guess at solutions or send customers elsewhere.

Big dealers and chain stores have the expensive tools but often put them in the hands of undertrained technicians. Having a $50,000 scanner doesn't make someone a good diagnostician any more than owning a stethoscope makes someone a doctor.

These tools also create new scam opportunities. Shops can claim they need "special factory equipment" to diagnose your problem, then charge premium rates for services that may not even be necessary. The complexity intimidates customers into accepting whatever they're told.

Software issues are particularly profitable for dishonest shops. A corrupted control module might cause symptoms that seem like multiple hardware failures. The honest approach is reprogramming or replacing the faulty module. The profitable approach is replacing every component the symptoms suggest might be bad.

I've seen shops charge customers for new sensors, actuators, and wiring harnesses when the real problem was corrupted software that could be fixed with a simple update. The customer pays thousands while the actual repair costs the shop maybe an hour of labor.

The technology complexity has created an arms race between manufacturers and repair shops. Each model year brings new systems, updated software, and proprietary procedures that require expensive equipment and training to service properly.

This creates barriers to entry that favor large operations over small independents. Chain stores and dealerships can afford the latest diagnostic equipment, while small shops get left behind with obsolete tools and incomplete technical information.

The result is consolidation of repair capability in fewer hands, which reduces customer choice and can increase prices. When only a few shops in an area have the equipment to diagnose certain problems, they can charge whatever the market will bear.

Manufacturers contribute to this problem by restricting access to technical information and diagnostic tools. They claim this protects consumers from unqualified repairs, but critics argue it's really about controlling the aftermarket and forcing customers back to dealers for service.

Potential Solutions

Despite systemic problems, several changes could improve the situation significantly.

Pay System Reform: Moving away from pure flat rate toward compensation that rewards diagnosis and customer satisfaction would help. Some progressive shops are trying hybrid models with base salaries plus quality bonuses instead of pure volume rewards.

Professional Licensing: Requiring mechanics to get and maintain individual licenses like other skilled trades would create accountability. License suspension or revocation would provide real consequences for bad work.

Training Requirements: Manufacturers could mandate ongoing education for warranty work, creating market pressure for shops to invest in employee development. Focus should be on systematic troubleshooting, not just parts identification.

Consumer Education: Government programs could teach basic car knowledge and scam recognition. This could be part of driver education or offered through community colleges.

Better Oversight: States could audit repair shops randomly and investigate complaints with meaningful penalties for fraud. This requires funding and political will to enforce effectively.

Technology Solutions: Digital platforms could track service histories and provide transparent pricing. Blockchain might enable tamper-proof maintenance records that follow cars throughout their lives.

The pay system reform is probably the most important potential change. The flat rate system creates perverse incentives that corrupt even well-intentioned people. Alternative compensation models could reward the behaviors customers actually want: accurate diagnosis, honest recommendations, and quality repairs.

Some shops are experimenting with hourly wages plus performance bonuses based on customer satisfaction scores, warranty rates, and other quality metrics. This approach requires more complex management but can create better alignment between mechanic incentives and customer interests.

Professional licensing for individual mechanics would create accountability that doesn't currently exist. When doctors, lawyers, or electricians repeatedly harm their clients, they can lose their licenses and be forced out of their professions. Auto mechanics face no such consequences, which enables bad actors to continue operating indefinitely.

A licensing system would need to include both technical competency testing and ethical standards enforcement. Mechanics who repeatedly perform unnecessary work or fraudulent billing could face license suspension or revocation, making it impossible for them to continue in the industry.

Consumer education could help level the playing field between customers and repair shops. Most people know almost nothing about how their cars work, which makes them vulnerable to sophisticated fraud schemes. Basic automotive education could help people recognize obvious scams and ask better questions about recommended repairs.

This education doesn't need to create shade-tree mechanics, just informed consumers who understand fundamental concepts about how vehicles operate and what types of maintenance they actually need.

The Path Forward

The auto repair industry stands at a crossroads. It can evolve toward greater honesty and competence, driven by educated consumers and progressive business practices. Or it can continue down the current path of systematic fraud enabled by complexity and regulatory failure.

The choice belongs to all of us - customers who demand better service, shop owners who prioritize integrity over short-term profits, and policymakers who recognize that transportation is too important to leave in the hands of predators.

The tools exist to create positive change. We just need the collective will to use them. The automotive repair industry serves a vital purpose in our car-dependent society. Modern vehicles are engineering marvels that can provide decades of reliable service when maintained properly. The people who service them should be respected professionals helping others, not predators seeking victims.

We have the knowledge to diagnose problems accurately, tools to fix them properly, and enough good people to provide honest service. What we lack is a system that encourages these positive qualities while discouraging fraud and incompetence.

Until fundamental changes happen, consumers must stay alert, learn about their cars, and support honest shops. Mechanics who maintain integrity despite a corrupt system deserve our business and respect. They show what the entire industry could become with proper incentives.

Reform won't be easy, but the goal is worth it - an auto repair industry based on competence, honesty, and real customer service. Our economy and communities benefit when this essential industry operates with integrity. The question isn't whether change is possible, but whether we have the will to demand it.

The honest mechanics are still out there. Find them, support them, and help them succeed. That's how we start fixing an industry that's been broken for too long. Every customer who rewards quality service with loyalty and referrals helps create demand for the kind of professionals the industry desperately needs.

The road ahead won't be smooth, but the destination - an automotive service industry worthy of the sophisticated machines it maintains - is worth whatever effort it takes to get there.